Have you ever been curious of how the utility lines (power line and similar ones) can end up underneath heavy traffic highways or even rivers without the slightest indication of excavation? Enter underground drilling, a technologically advanced process with the ability to be unnoticeable, but nevertheless transform the way infrastructure is put in place.

Understanding the Basics of Underground Drilling

Underground drilling is a design process of placing utilities under the ground without affecting the ground in any way. It is perceived to be a non-invasive way to lay pipelines, cables, and conduits over terrains of diverse kinds. You may also refer or know it as the directional drilling, horizontal boring or trenchless technology and although they can be said interchangeably with one another; they bring with them slight differences.

Common Terms: Directional Drilling, Horizontal Boring, and Trenchless Technology

- Directional drilling, often shortened to HDD, is a method of drilling along a predetermined path below the surface. It’s commonly used to steer the drill horizontally.

- Horizontal boring emphasizes the level direction of the drill, especially useful under roads or buildings.

- Trenchless technology is the umbrella term for all no-dig methods, including pipe bursting and micro-tunneling, in addition to HDD.

These technologies have invented the necessity to rip up landscapes, roads, or properties, and so they are particularly useful in urban or ecologically vulnerable locations.

The Underground Drilling Process: Pilot Hole → Reaming → Product Installation

Here’s how it works:

- Pilot Hole Creation: A small-diameter drill bit is guided along a pre-mapped path underground.

- Reaming: The initial hole is expanded using a reamer to accommodate the utility that will be installed.

- Product Pullback: The utility pipe or cable is then pulled through the enlarged hole from the exit point back to the starting location.

It’s an exact, less invasive procedure, relying on sensitive planning and operation, especially when faced with difficult terrain or immediately vested areas.

Key Applications of Directional Drilling

Installing Critical Utilities with HDD

Whenever you turned on a tap, powered a phone or logged onto the internet, chances are good that underground drilling made its contribution. Typical applications of directional drilling are made to install:

Water Lines and Sewer Systems

Cities are now utilizing HDD over more traditional methods of digging under road ways to lay new sewer lines or to repair some old water main systems without halting traffic or leaving a major surface scar. In urban areas where the underground infrastructure will have to be threaded among layers of complex existing infrastructure pipes, this is extremely important.

Gas Pipelines and Electrical Conduits

Safety and reliability are the major priorities of utility providers. Horizontal boring gives them the means to securely set gas lines or high-voltage electrical conduits below streets, structures and other natural terrains such as streams and hills, keeping utilities secure and communities intact.

Fiber Optic and Telecommunication Cables

In the contemporary world, high speed and fast internet is a necessity. Telecommunication firms also install fiber optic cables especially in populated regions with the use of the trenchless technology which is often installed without digging trenches and disrupting normal life.

Real-World Applications of Horizontal Directional Drilling

HDD is not a dream anymore; it is creating real-world projects that are more efficient, less time consuming, and safer.

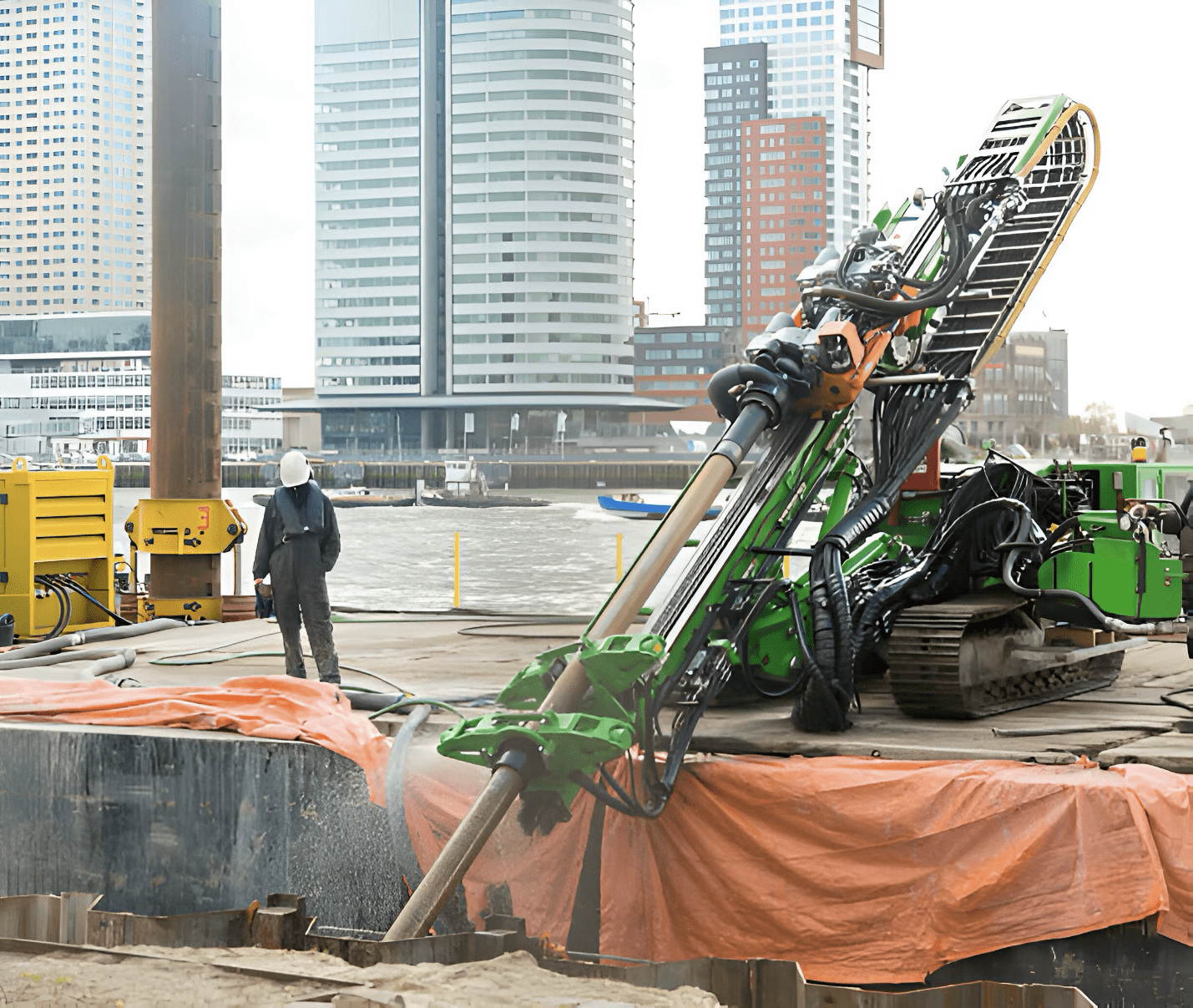

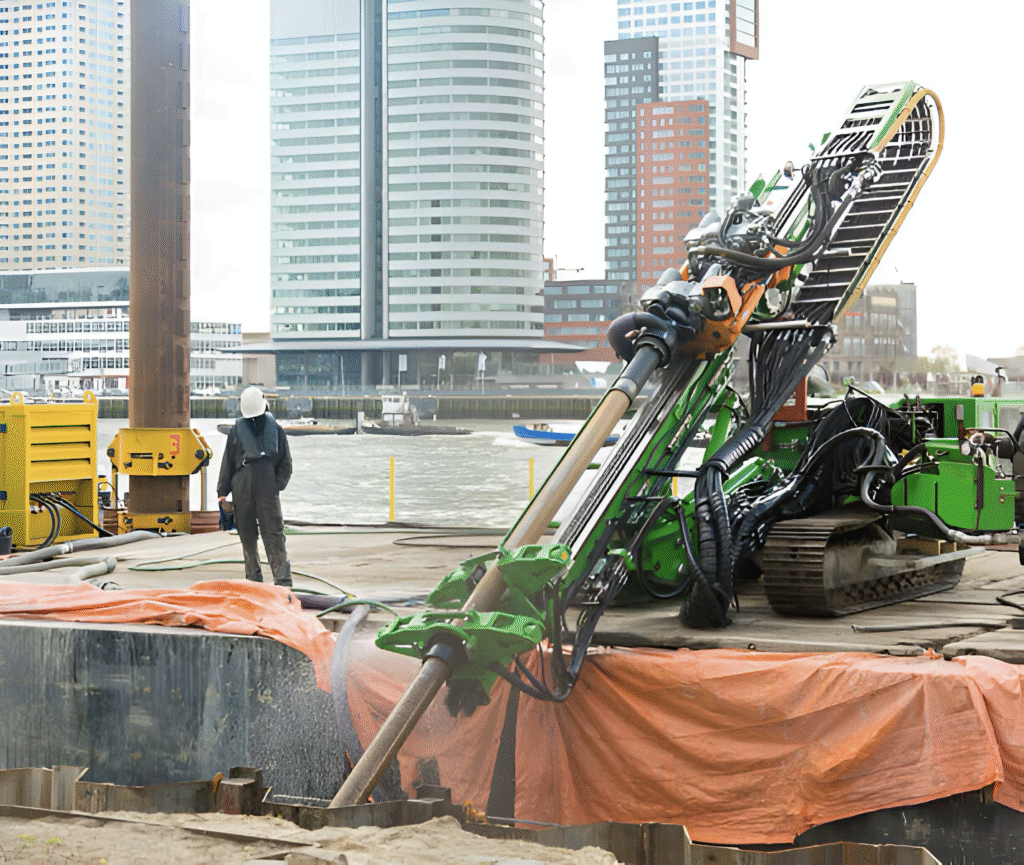

Road, River, and Building Crossings

Consider having to lay a sewer pipe through a 6-lane highway or across a river. The conventional trenching would imply gigantic road suspensions of traffic or extensive bridge construction. Under these obstacles the teams can be accurately directed using directional drilling. There are projects that run HDDs under the train track connecting islands to mainland or one way without disrupting the service.

Advantages of Directional Drilling vs. Traditional Trenching

Less Surface Disruption

Unlike conventional trenching wherein the ground would have to be excavated along a long distance, underground drilling does not dig the surface too much. That translates to not having roads, sidewalks and front yards in shreds. City planners and homeowners all like this more respectable and less-dusty method of performing work on the infrastructure.

Faster Project Completion

The directional drilling is usually quicker as compared to trenching. Why? The preparation is smaller, no monumental digging is required and there are fewer weather and surface-related delays. Things that took weeks before are now completed within few days.

Lower Environmental Impact

Among the unscattered advantages of HDD is that it has a lower environmental impact. It does not need large scale digging; thus, it suits wetlands, parks and nature reserves. This particular method reduces erosion, run-off, and the disturbance to the local wildlife.

Reduced Restoration Costs

Once the trenching has been done, it is the duty of the site to be replenished with the trenching back with repaved roads, re-sodded lawns and reconstructed sidewalks. The expenses accumulate. Most of the above-mentioned problems are avoided by HDD, which greatly reduces the price of repair and cleanup after the installation.

Improved Safety and Accessibility

Conventional trenching leaves open trenches and obstructions, which are not only unsafe to employees but also to the community. Horizontal boring reduces the risks to a bare minimum and thus has a safer working environment. Besides, roads and sidewalks remain open during the project.

Ideal Use Cases & Challenging Terrains

Urban Infrastructure Solutions

Contemporary cities are a maze of streets, infrastructure, structures and human beings. Provision of new lines in this landscape without closing major junctions is difficult unless there is an underground drilling. It is made to fit in narrow places and through dense underground areas.

Navigating Wetlands, Rivers, and Sensitive Areas

Digging in a wetland or a forest under protection is not an option. That is where directional drilling excels. Underground installation of utilities can be done by digging below the ground surface so that it does not destroy the aesthetic nature and ecological stability of the region.

Overcoming Barriers with Advanced Navigation Techniques

The modern HDD rigs have GPS, sonar and other tracking devices to make their way through the rock, clay and rugged terrain. This also qualifies them to be used in mountainous regions, locales with a complicated geology, and other such difficult terrains where trenching is not the solution.

Common Misconceptions About Underground Drilling

Despite its rising popularity, the underground drilling is usually not understood. Let’s put a pin in a few of the biggest myths surrounding this marvel of modern technology.

It’s Not Just for Large-Scale Projects

Most individuals believe that directional drilling is applicable in huge infrastructure projects. Consider: great highway, bridges, or multi-city pipelines. But here is the reality, it is just as applicable to smaller jobs such as residential sewer line construction, commercial fiber line or local water connection.

With the development of technology, HDD rigs are now availed in different sizes with the compact rigs fitting in congested areas and the more elaborate path fitting in the larger rigs. That is why even local governments or small businesses as well as certain home-owners may access this effective approach. It is no longer a game reserved only to the big players.

It’s Not Always More Expensive

Horizontally boring may appear more expensive than conventional trenching at first. This makes sense, as it is run by sophisticated equipment and it needs well trained employees. When you consider the overall cost of the whole project which entails the restoration costs, surface-disruption permits and the cost of delaying the project HDD sometimes prevails.

Taking, as an example, opening a city street to lay pipe does not merely need labor and materials, but also repaving, and rerouting traffic, plus inspection. With trenchless option, you eliminate most of those headaches and costs. The initial investment in the long term proves to be a big payoff.

HDD Projects Offer Long-Term Durability

It has the myth that HDD is not as durable when conducting underground installations. These systems are designed in fact to be durable. Materials found in pipes and conduits employed in underground drilling jobs normally include high-density polyethylene (HDPE), stainless steel or reinforced PVC, which are materials that stand pressure, moisture, and movement of the soil.

In addition, the installation itself stirs up as minimum stress on the product. As the pipe is not forced into the ground through rocky or calamitous ground, there is less risk of getting damaged or weakened. It goes more smoothly-and reliably.

Conclusion

Underground drilling, sometimes referred to as directional drilling, horizontal boring or trenchless technology, is a paradigm-shifter in the utility installation industry. Whether it is through water lines and gas mains or fiber optic cable and sewer lines, this new approach is changing the way we think about infrastructure and particularly, infrastructure built in areas where there is limited space or environmental concerns.

Relatively, it has shorter timescales compared to the conventional trenching, has fewer negative effects on the environment, is safer, and has substantial long-term cost advantages. It is not only applicable in large-sized jobs. HDD precision and efficiency is applicable even in providing services to small communities and business ventures with the right technique.

With population increasing in urban surroundings and the need to have a good infrastructure that can be depended upon, underground drilling is one such intelligent decision that can be of use. Be it a local government interested in plotting out the next public works project or a contractor seeking a more efficient means of installation that provided a safer environment then it is time to look into the possibilities of HDD.

Underground Drilling LLC is a reliable source of information about the trenchless industry where you can read more or start with your next project.

Frequently Ask Questions

What is the difference between underground drilling and trenching?

The difference between underground drilling and trenching is that underground drilling involves putting the utilities underground without surface excavation, whereas during trenching open excavation is required. In some urban, or sensitive areas, drilling is less disturbing and may even be quicker.

Is directional drilling safe for residential areas?

Directional drilling is so safe even in residential areas. It is accurate, causes minimal disturbance to the surface and eliminates risks such as slip injuries or damage to structures such as buildings, walls, and roads because of open trenches.

How long do HDD installations last?

Well installed HDD systems have the potential to persist decades, frequently 50 years or more. The materials are of high durability and the process of installation cuts culminate on wear and tear during installation.

What are the risks of using horizontal boring?

The well installed HDD systems have the potential to serve over decades or more than 50 years. Raw materials are very tough and during installation, wear and tear are minimal.

Can HDD be used in rocky or mountainous terrains?

Absolutely. HDD in modern rigs has special drill heads and tracking system to work around hard soils, rock and undulating topography. It is one of the most effective ways of tackling versatile grounds.